search

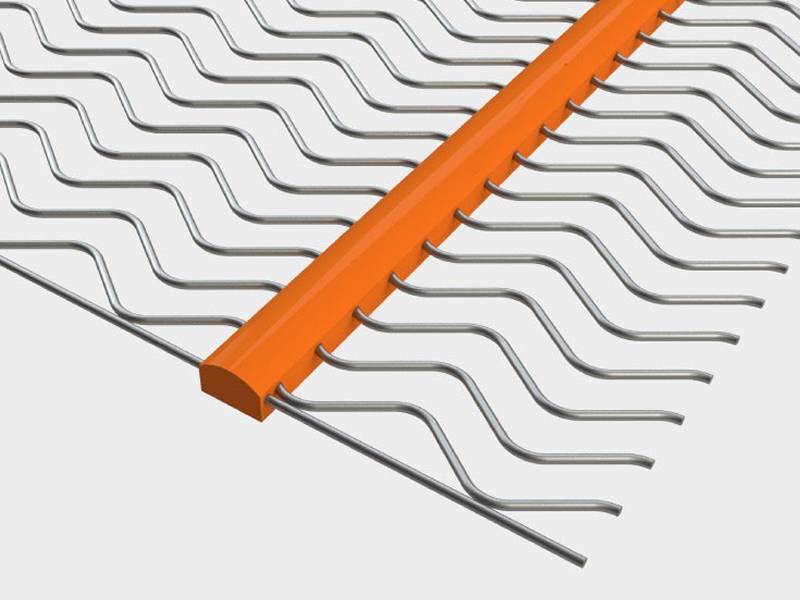

Wave Wire Self-Cleaning Screen is made with crimped wires placed parallel to each other. This delivers a very large screening area but lower precision. It is highly recommended for screening fines. It is typically used in small aperture sizes and in end tension decks.

| Aperture (mm) | Wire Diameter (mm) | Weight (kg/m2) | Open Area (%) |

|---|---|---|---|

| 1.50 | 1.20–1.25 | 3.8 | 50 |

| 1.75 | 1.20–1.25 | 3.5 | 55 |

| 2.00 | 1.20–1.60 | 3.3–4.8 | 51–57 |

| 2.50 | 1.20–2.00 | 3.1–5.9 | 53–60 |

| 3.00 | 1.20–2.00 | 2.8–5.4 | 57–64 |

| 3.50 | 1.20–2.00 | 2.5–5.4 | 57–67 |

| 4.00 | 1.20–2.00 | 2.3–4.8 | 62–70 |

| 4.50 | 1.20–2.00 | 1.9–4.5 | 64–75 |

| 5.00 | 1.50–2.80 | 2.7–8.2 | 56–71 |

| 5.50 | 2.00–2.50 | 4.1–6.2 | 61–67 |

| 6.00 | 1.50–2.80 | 2.5–7.1 | 60–73 |

| 6.50 | 2.00–2.50 | 3.7–5.6 | 64–70 |

| 7.00 | 2.00–3.15 | 3.4–6.4 | 67–72 |

| 7.50 | 2.00–3.00 | 2.2–6.9 | 62–63 |

| 8.00 | 2.00–3.15 | 3.1–6.1 | 69–74 |

| 8.50 | 2.00–2.50 | 2.8–4.3 | 73–77 |

| 9.00 | 2.00–3.15 | 2.7–6.0 | 69–79 |

| 10.00 | 2.00–3.15 | 2.5–5.2 | 73–80 |

| 11.00 | 2.80–3.15 | 1.9–4.9 | 75–85 |

| 12.00 | 2.50–4.00 | 2.0–7.2 | 71–84 |

| 12.50 | 2.50–4.00 | 3.1–7.2 | 71–80 |

| 13.00 | 2.00–3.00 | 3.3–4.3 | 71–74 |

| 14.00 | 2.50–4.00 | 2.9–6.7 | 73–82 |

| 15.00 | 2.50–4.00 | 3.1–6.4 | 74–80 |

| 15.50 | 3.00 | 3.8 | 80 |

| 16.00 | 3.00–4.00 | 3.9–6.4 | 75 |

| 17.00 | 3.00–4.00 | 3.8–6.2 | 75–80 |

| 18.00 | 3.00–4.00 | 3.7–5.6 | 78–80 |

| 19.00 | 3.00–4.00 | 3.4–5.5 | 78–82 |

| 20.00 | 3.00–4.00 | 2.2–5.2 | 79–86 |

| 22.00 | 3.00–4.00 | 3.0–5.0 | 80–84 |

| 24.00 | 4.00 | 4.8 | 81 |

| 25.00 | 3.00–4.00 | 2.8–4.7 | 81–85 |

| 27.00 | 4.00 | 4.2 | 83 |

| 28.00 | 4.00 | 4.1 | 83 |

| 30.00 | 3.00–4.00 | 2.2–3.8 | 85–87 |

| 35.00 | 4.00–5.00 | 3.4–5.2 | 83–86 |

| 40.00 | 4.00 | 2.7 | 89 |

| 45.00 | 4.00 | 2.5 | 90 |