search

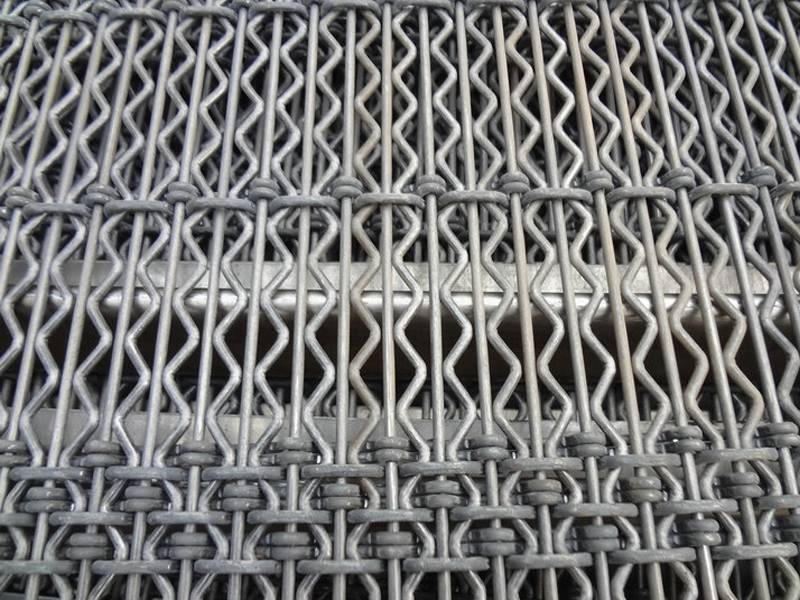

Supported Square Self-Cleaning Screen is much like the square self-clean wire mesh but its precision is increased with the addition of a straight wire in-between its crimped wires, which maintains the correct aperture size under heavy loads and high impact material screening. Its more precision classification prevents wedging of elongated particles.

| Aperture (mm) | Wire Diameter (mm) | Weight (kg/m2) | Open Area (%) |

|---|---|---|---|

| 1.50 | 1.20–1.25 | 4.8–5.5 | 29–37 |

| 1.75 | 1.20–1.25 | 4.5–5.3 | 40 |

| 2.00 | 1.20–1.60 | 4.3–6.3 | 36–43 |

| 2.50 | 1.20–2.00 | 3.8–8.0 | 37–49 |

| 3.00 | 1.20–2.00 | 3.5–7.6 | 38–54 |

| 3.50 | 1.20–1.60 | 3.4–5.4 | 47–56 |

| 4.00 | 1.20–2.50 | 3.0–9.2 | 42–60 |

| 4.50 | 1.50–2.50 | 4.0–7.5 | 46–58 |

| 5.00 | 1.50–2.80 | 3.9–9.1 | 45–59 |

| 5.50 | 1.50–2.50 | 3.0–6.7 | 52–65 |

| 6.00 | 1.50–3.15 | 3.0–10.7 | 45–66 |

| 6.30 | 2.50–2.80 | 7.4–8.2 | 51–52 |

| 6.50 | 2.00–2.50 | 5.1–6.2 | 56–59 |

| 7.00 | 2.00–3.15 | 4.0–11.6 | 47–64 |

| 7.50 | 2.00–2.50 | 5.50 | 60 |

| 8.00 | 2.00–4.00 | 4.4–10.9 | 50–65 |

| 8.50 | 2.00–2.50 | 5.1 | 64 |

| 9.00 | 2.00–3.15 | 4.8–7.7 | 58–65 |

| 9.50 | 2.50–2.80 | 6.10 | 62 |

| 10.00 | 2.00–3.15 | 4.7–7.8 | 60–66 |

| 11.00 | 2.80–3.15 | 6.7 | 64 |

| 11.50 | 2.50–3.15 | 5.9 | 66 |

| 12.00 | 2.50–4.00 | 4.0–9.0 | 60–72 |

| 12.50 | 2.50–4.00 | 5.6–8.3 | 62–68 |

| 13.00 | 2.00–3.15 | 3.7–6.7 | 65–73 |

| 14.00 | 2.80–4.00 | 5.2–7.7 | 65–70 |

| 15.00 | 2.80–4.00 | 4.4–7.3 | 67–73 |

| 16.00 | 3.00–4.00 | 5.9–8.6 | 65–70 |

| 17.00 | 3.00–4.00 | 6.7 | 69 |

| 18.00 | 3.00–3.15 | 6.4–8.0 | 68–71 |

| 19.00 | 3.00–4.00 | 6.2 | 72 |

| 20.00 | 3.00–4.00 | 3.2–7.5 | 70–79 |

| 21.00 | 3.00–4.00 | 5.7 | 74 |

| 22.00 | 3.00–4.00 | 5.6–8.2 | 70–74 |

| 23.00 | 3.00–4.00 | 5.7 | 75 |

| 24.00 | 3.00–4.00 | 5.7–7.1 | 71–74 |

| 25.00 | 3.00–4.00 | 5.5–6.6 | 73–75 |

| 26.00 | 4.00 | 6.5 | 74 |

| 30.00 | 4.00–5.00 | 5.4–8.0 | 74–78 |